Sillybutts Breacher Hardware Kit BETA

Sillybutts Breacher Hardware Kit BETA

LEAD TIME: 1-2 BUSINESS DAYS

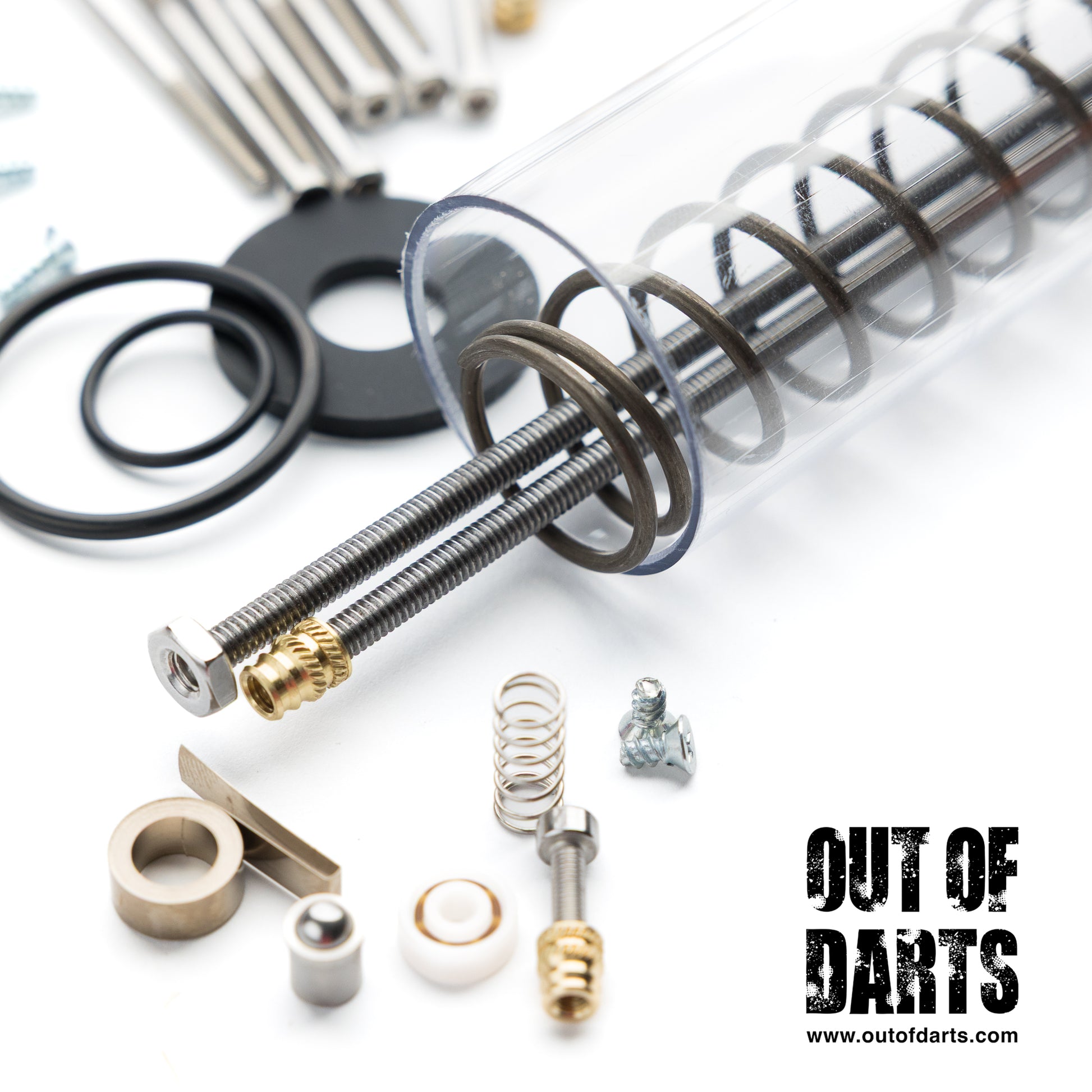

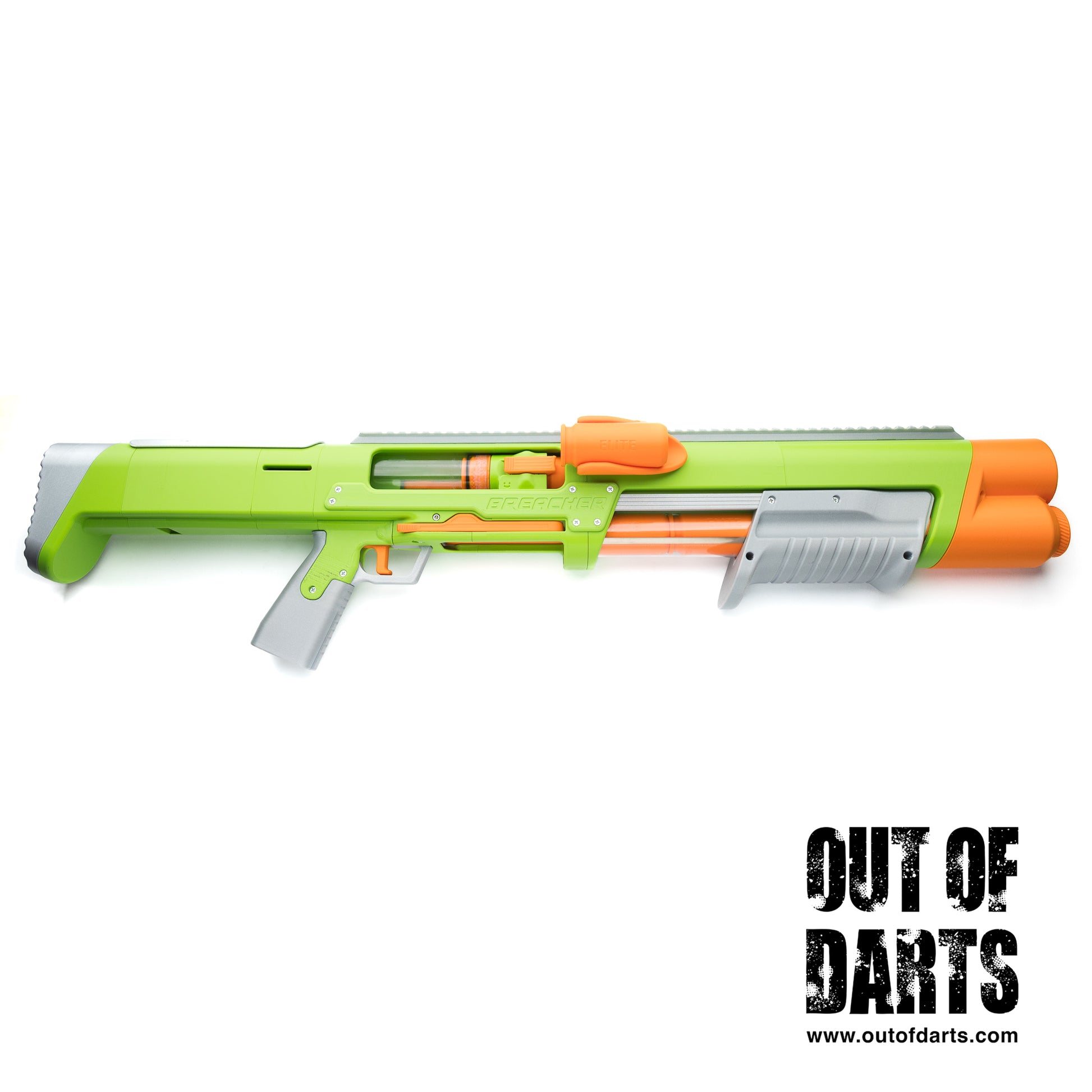

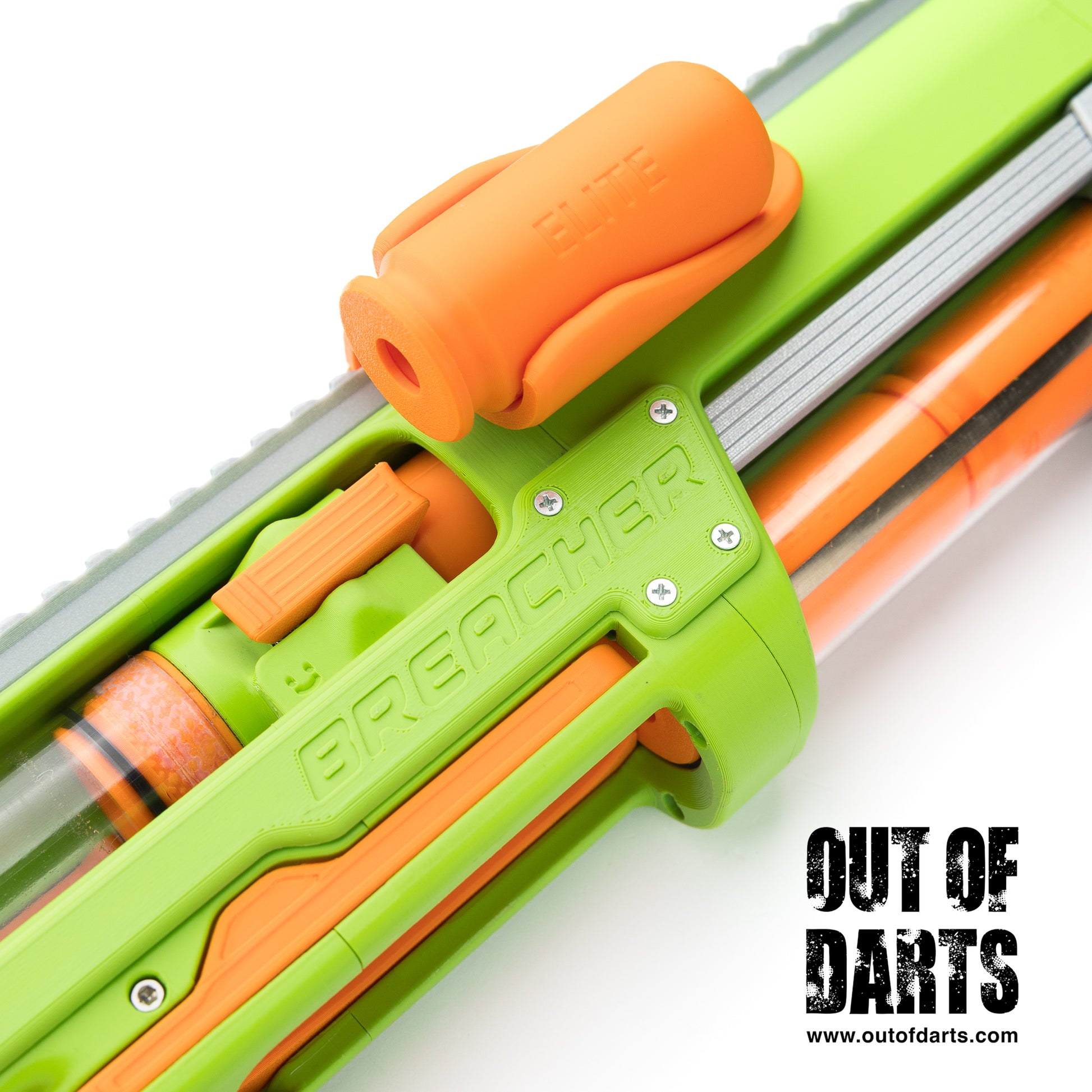

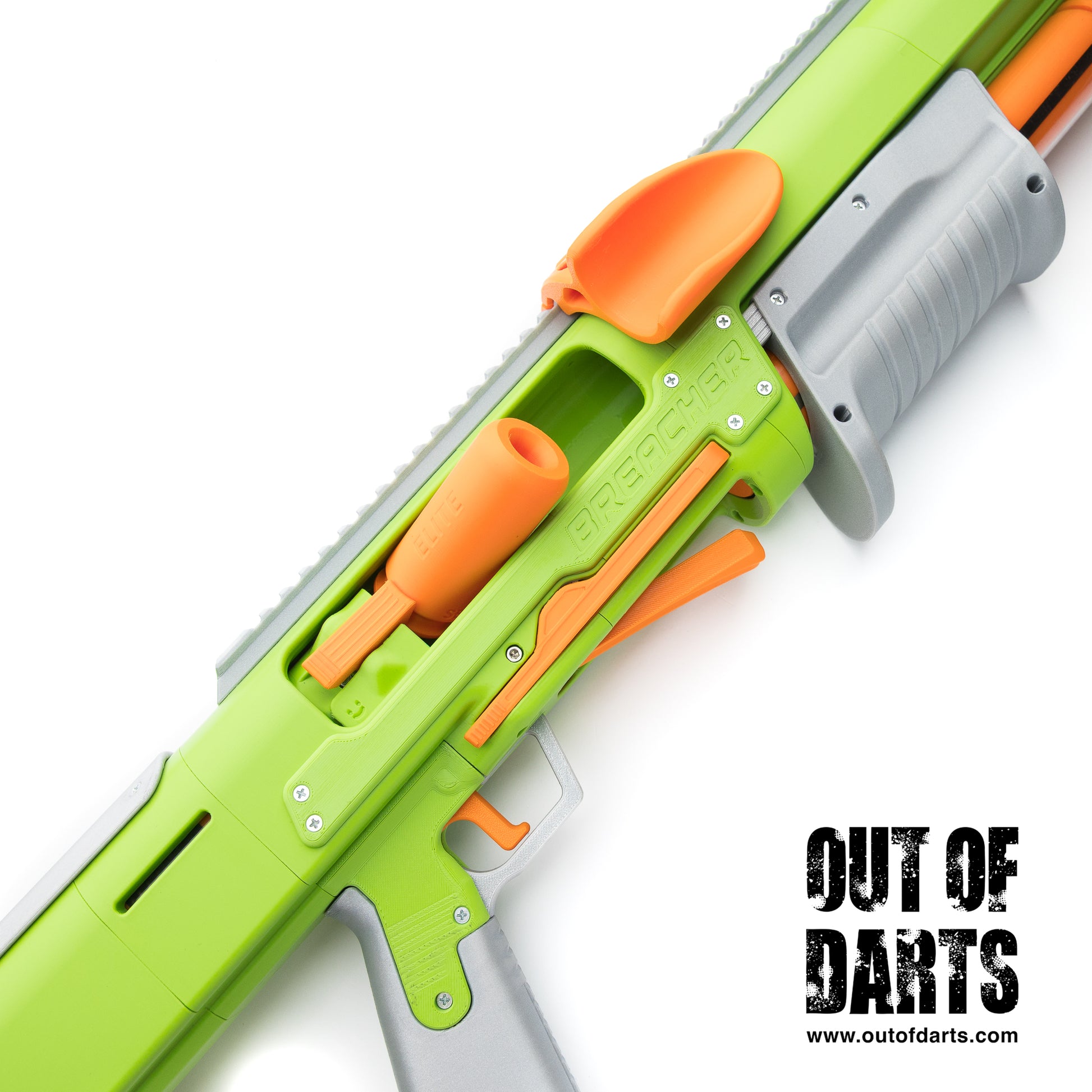

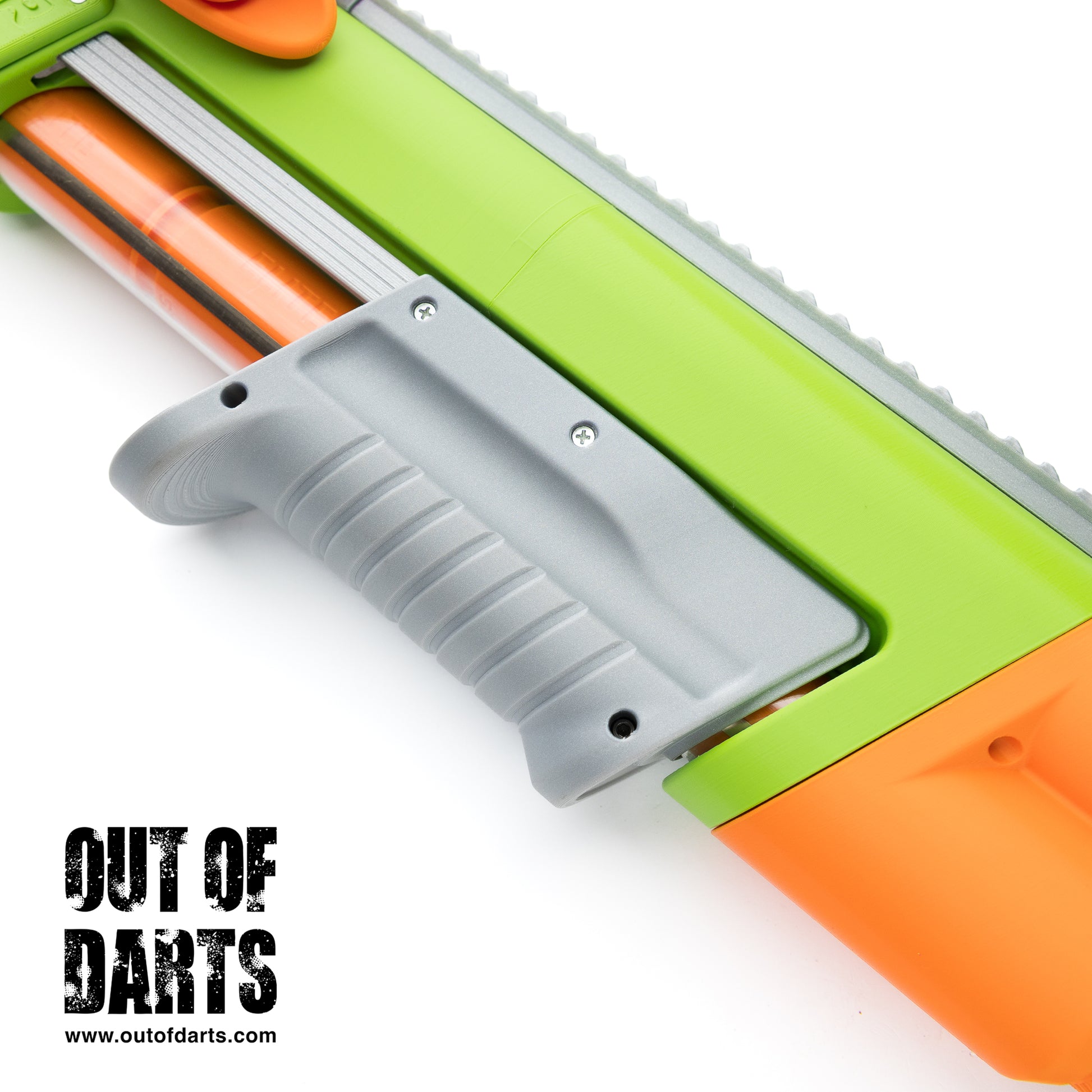

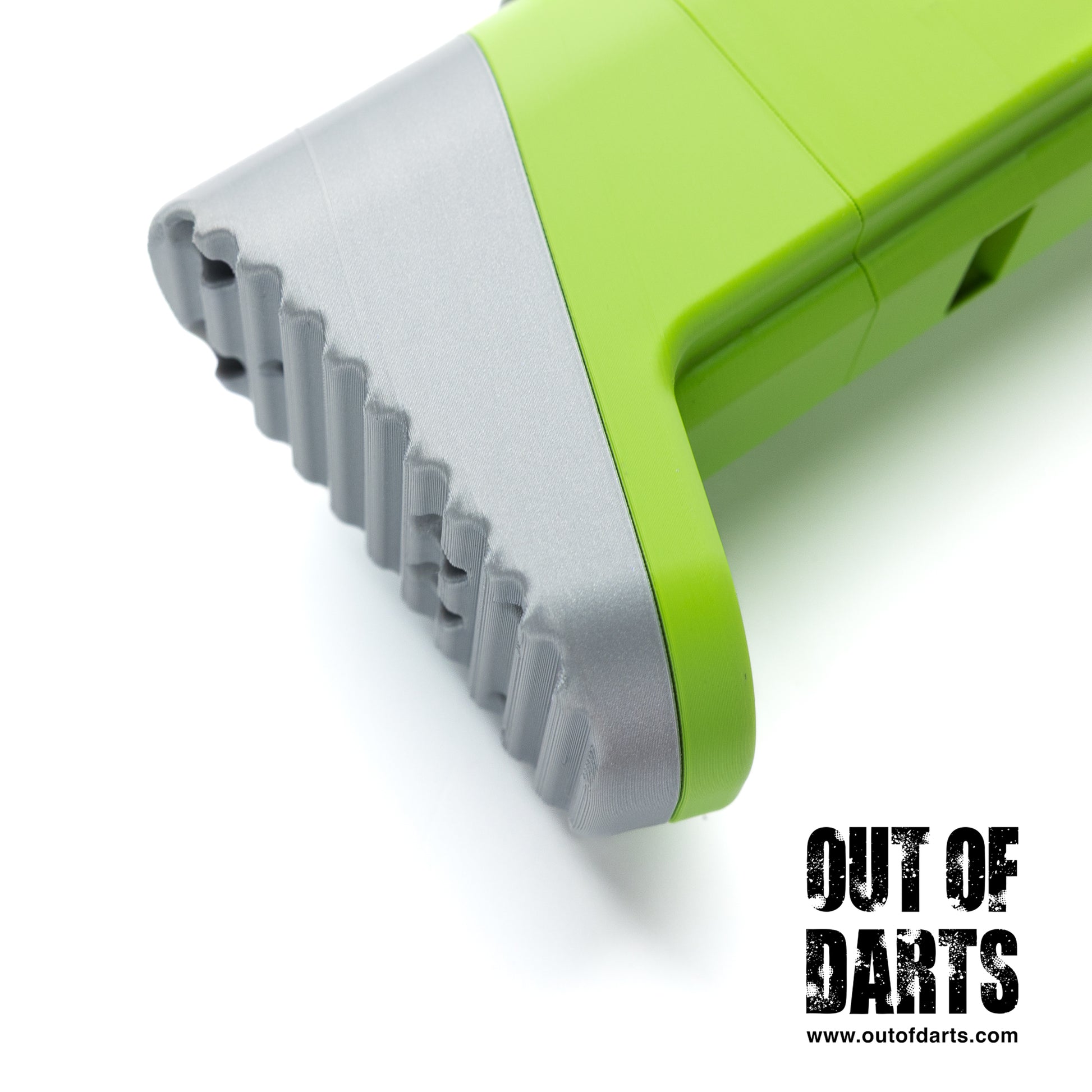

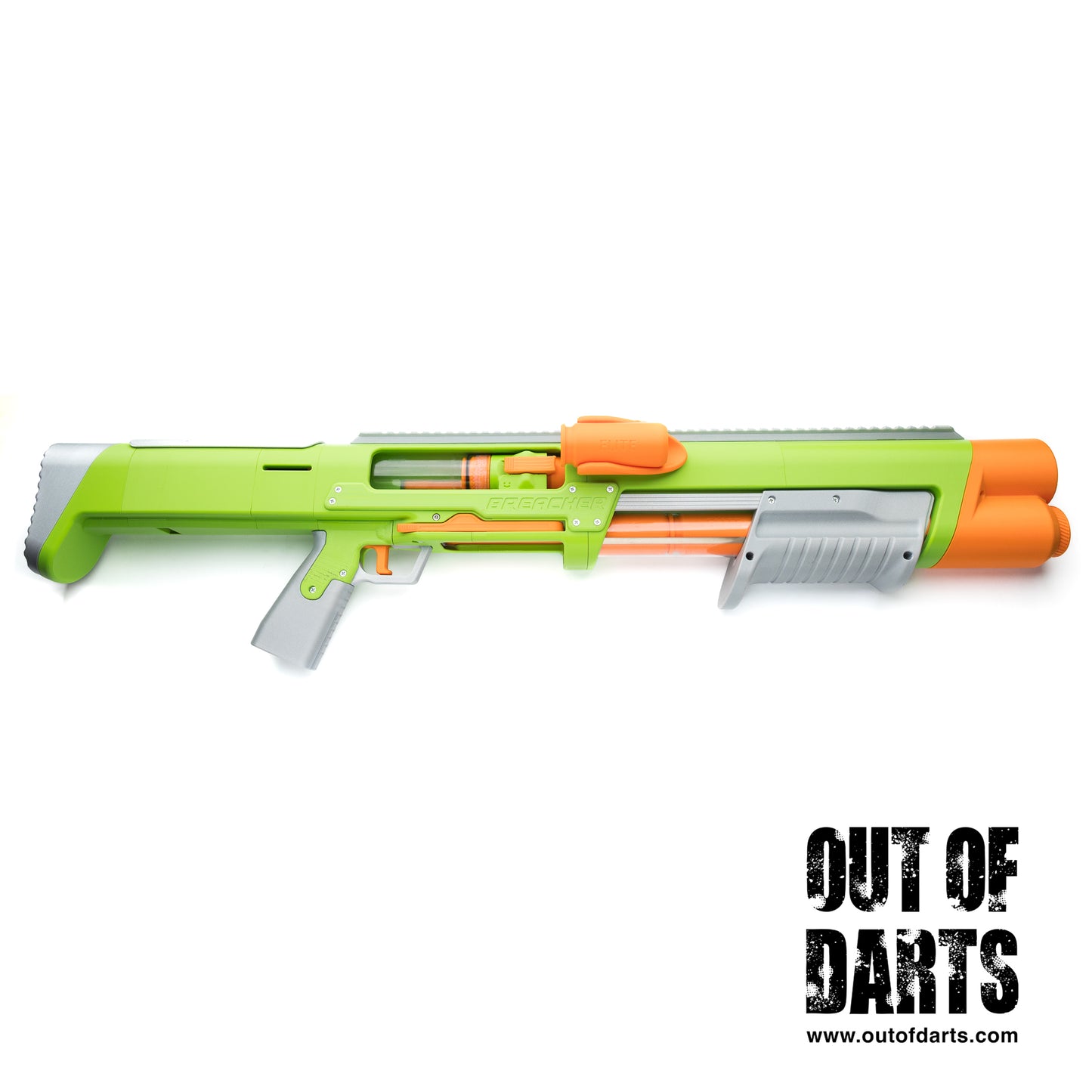

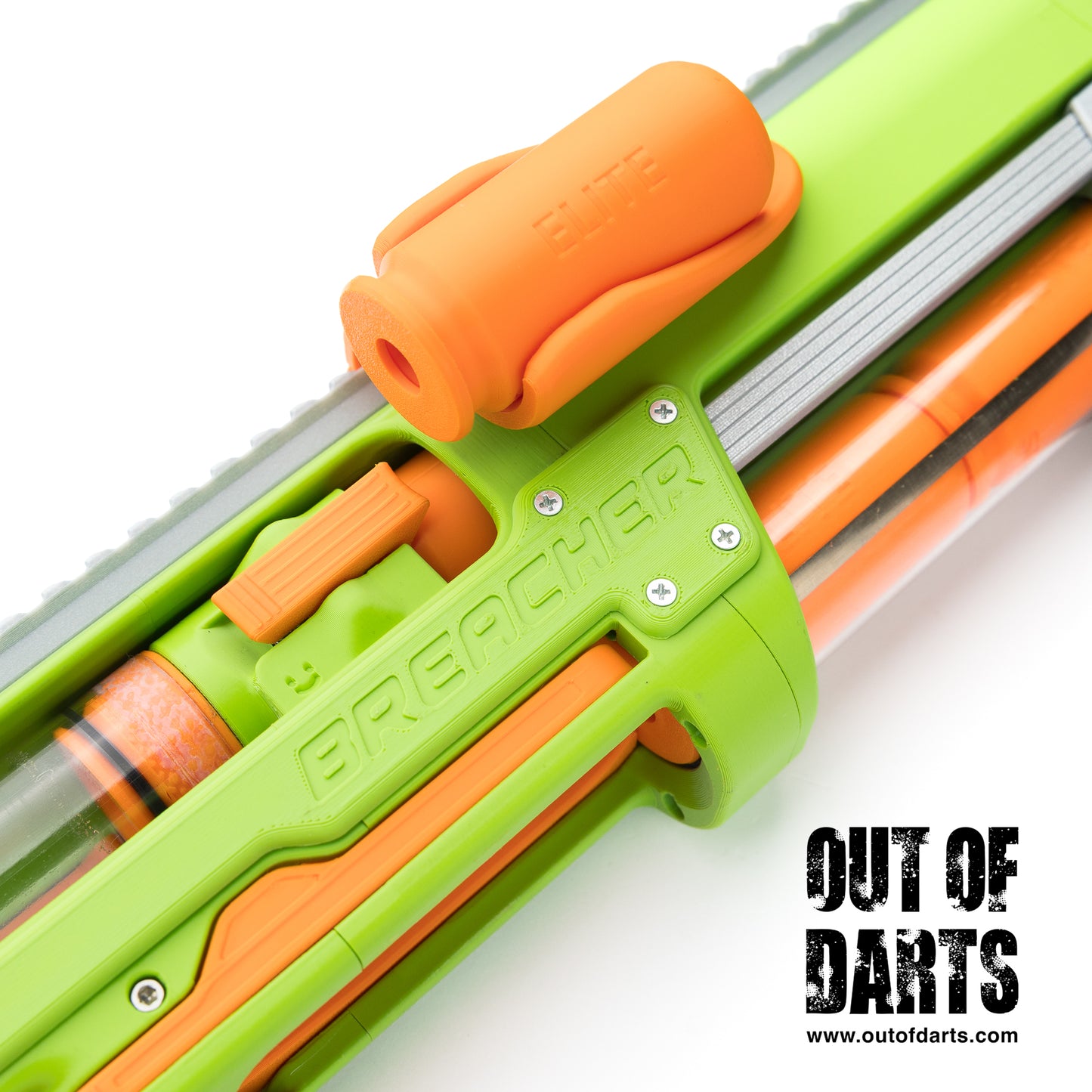

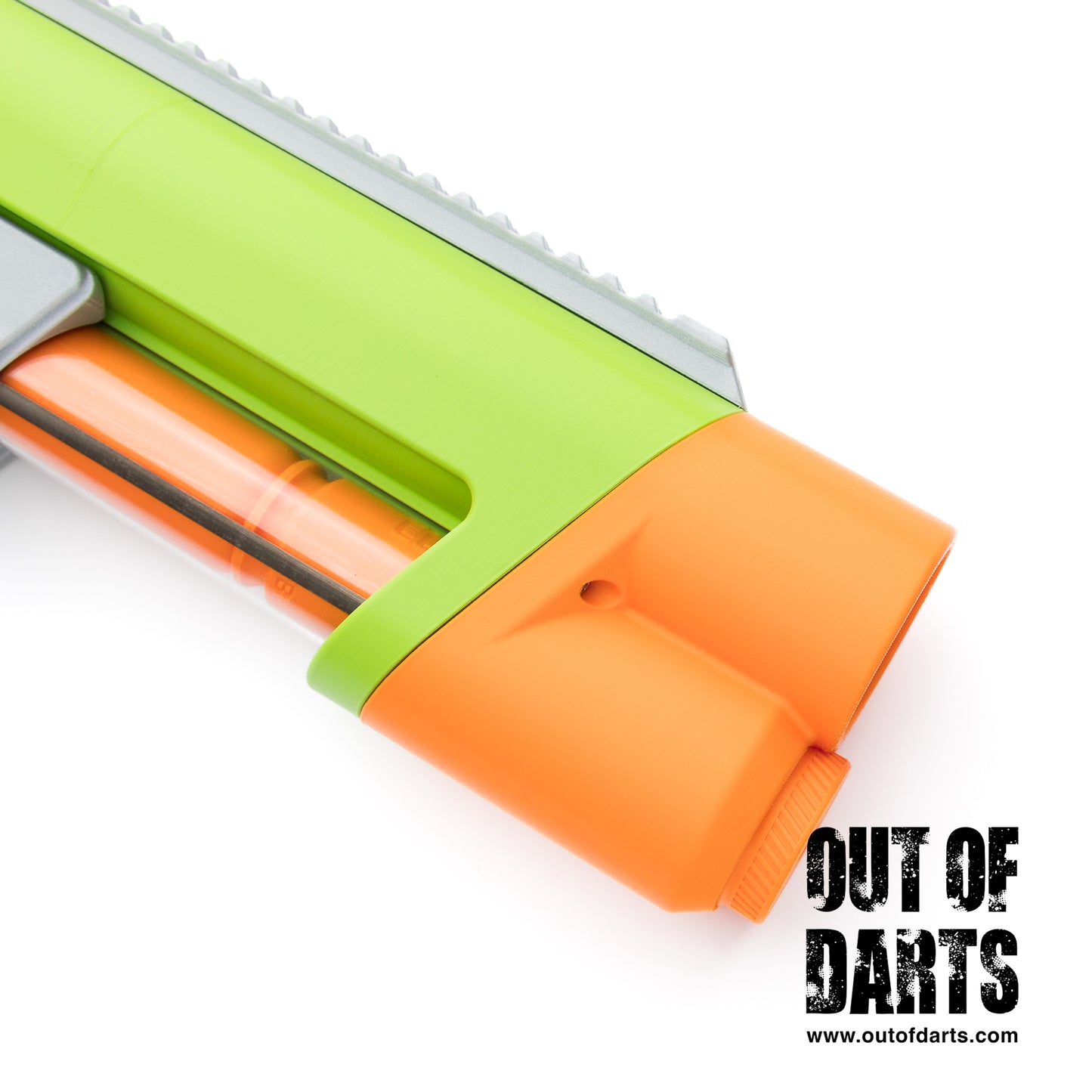

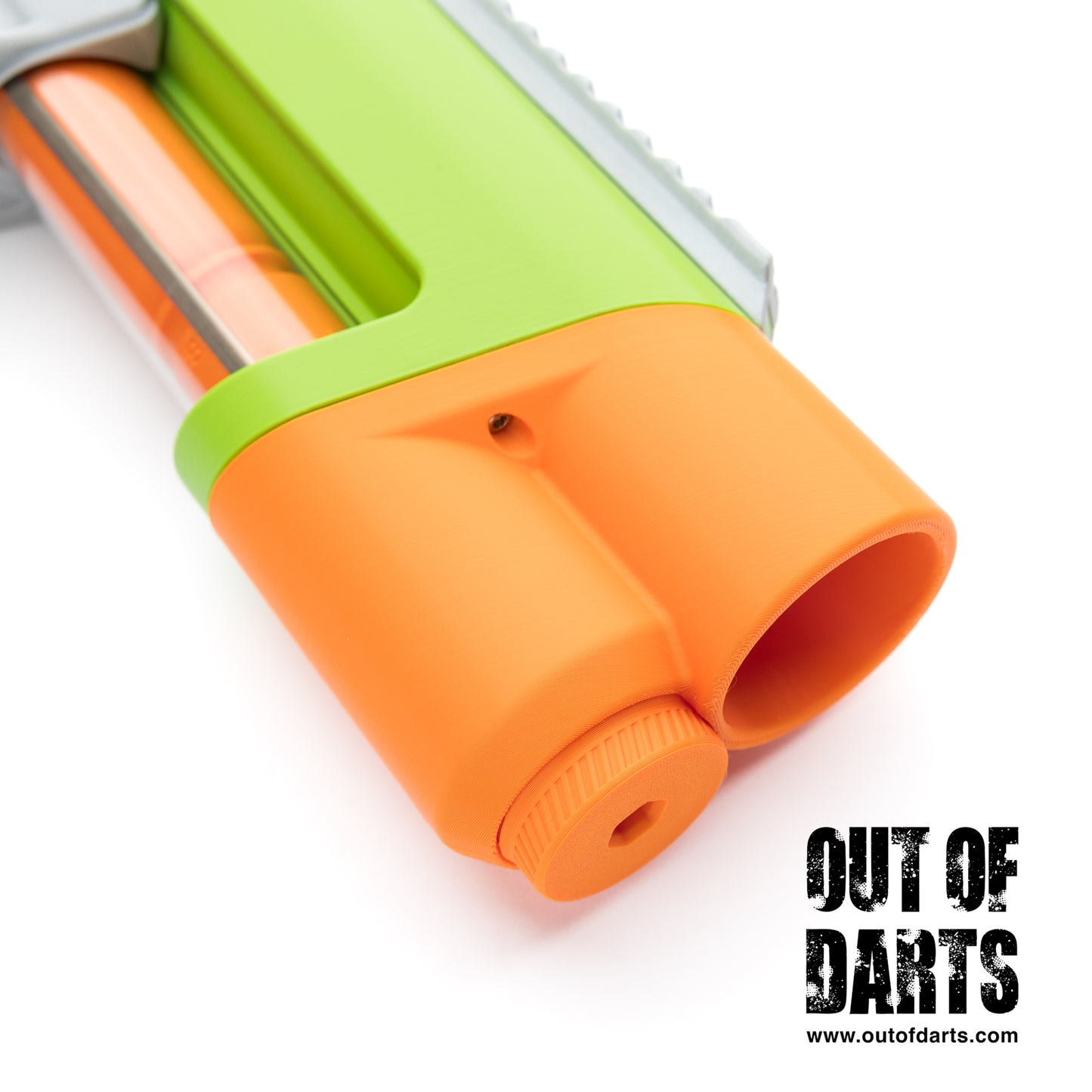

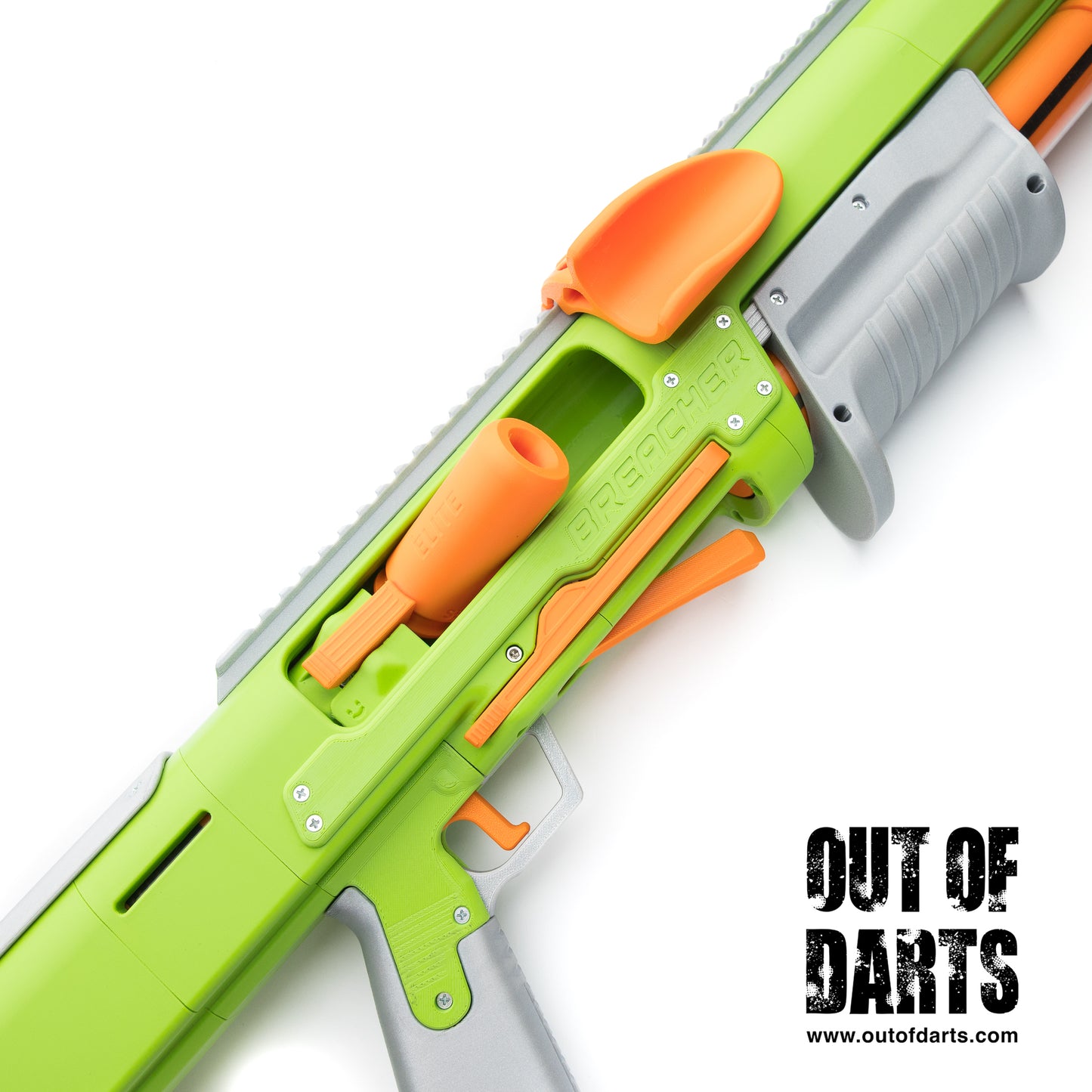

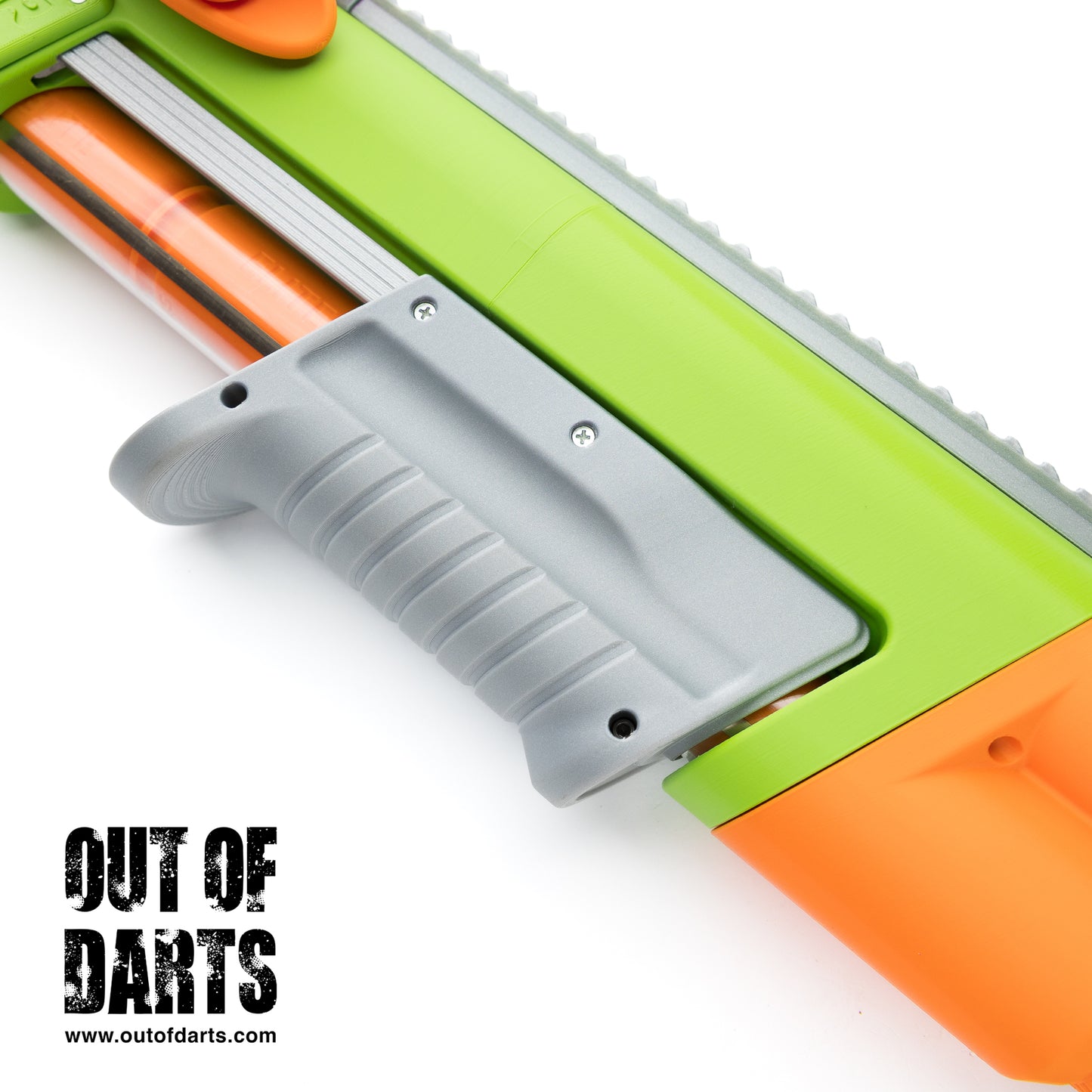

The Sillybutts Breacher is a shell-ejecting pump-action spring-powered blaster currently in an open beta release. Featuring an expandable tube magazine and lifter mechanism, this blaster is ultimately what Sillybutts had in mind when he designed his Silly Shells. Complete with bearing-assisted prime and constant-force mag springs, this shotgun-style blaster features a smooth and satisfying action. Additionally, its intimidating size and aesthetic match the power and versatility that can adapt to the ammo needs of any game or play style.

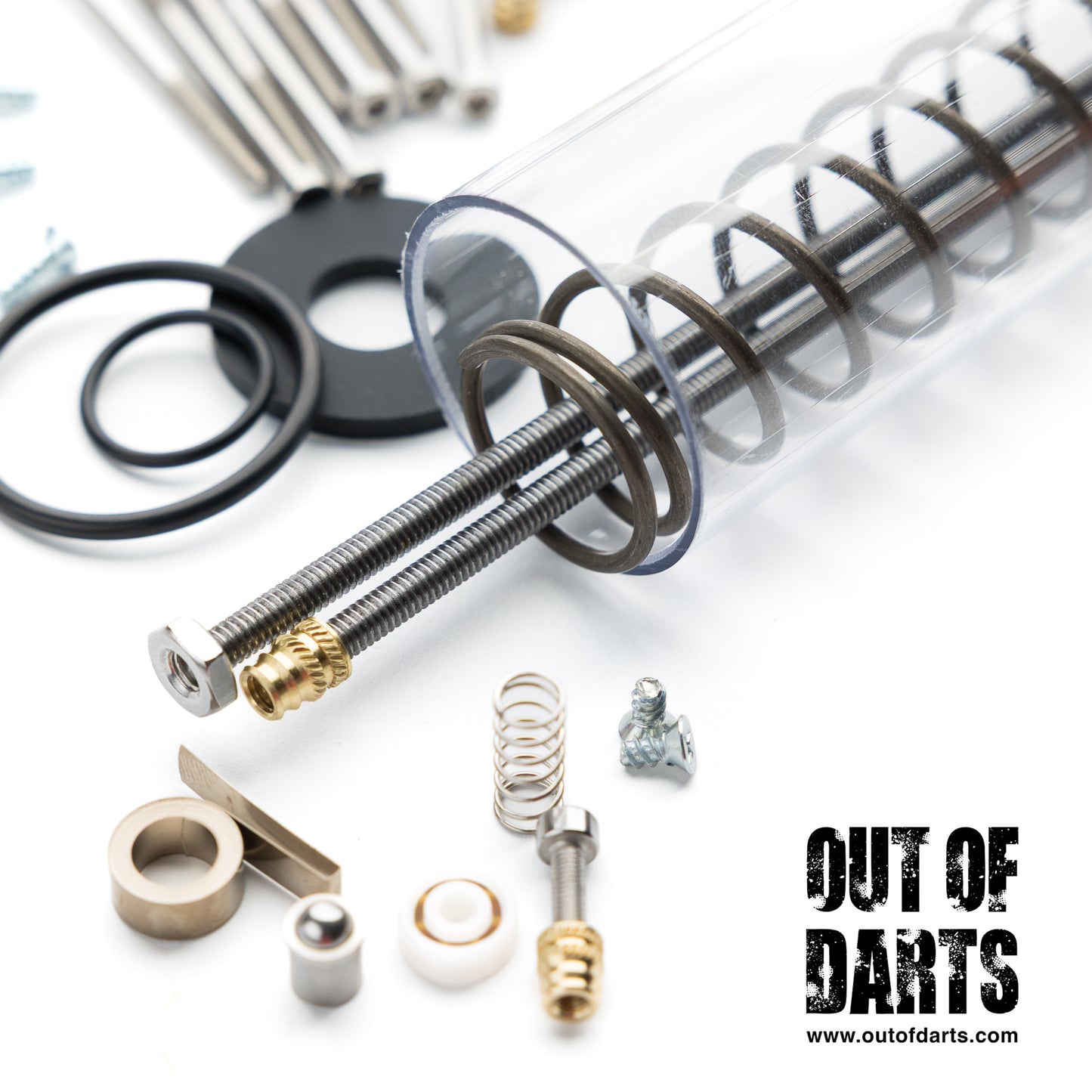

This hardware kit includes everything you need to print the 3D parts and assemble this blaster yourself (3D files available below). If you would like us to print the 3D parts for you, check out our 3D Parts + Hardware Kit!

FEATURES:

• Sillybutts Breacher Hardware Kit

• Pump-action shell-fed blaster

• Open beta release!

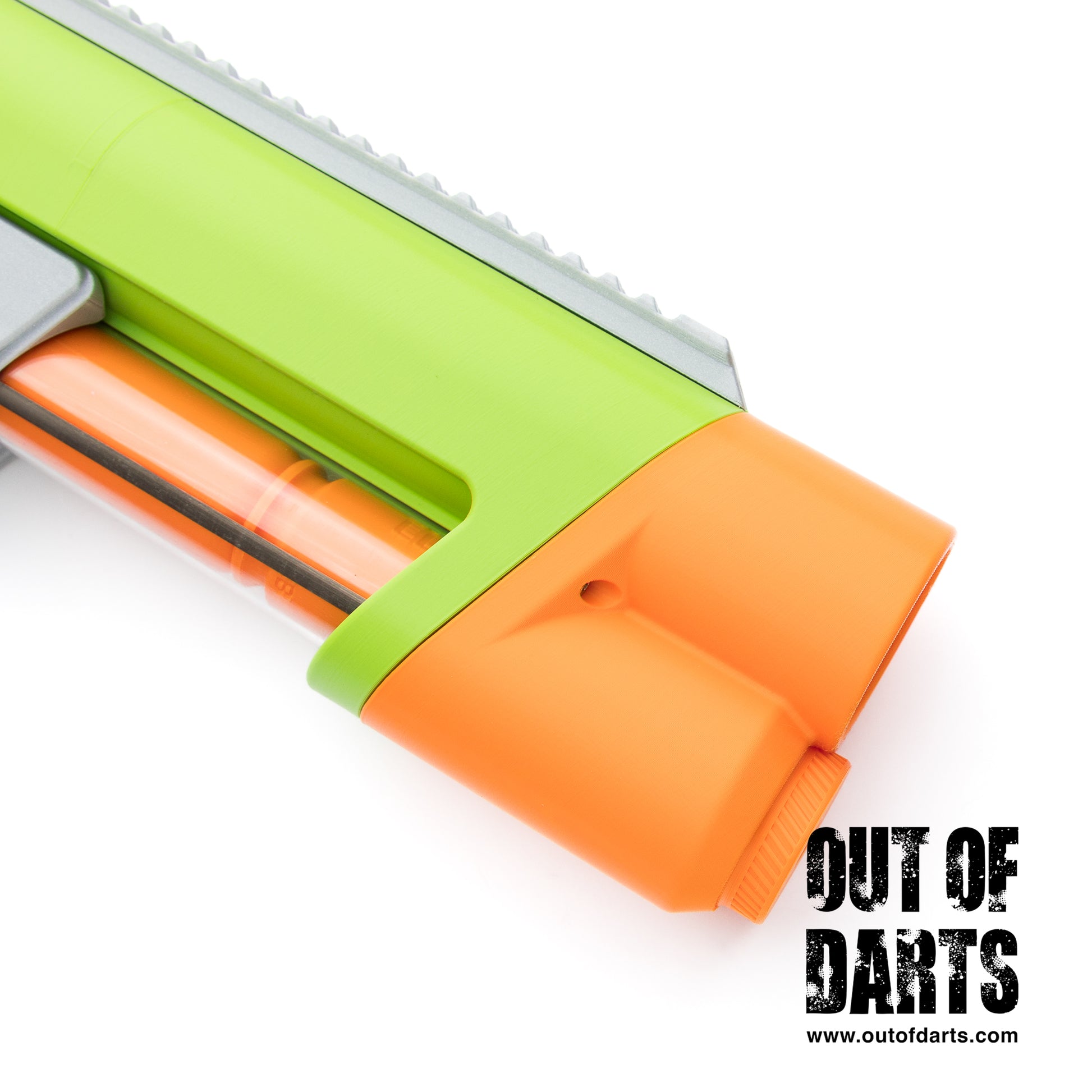

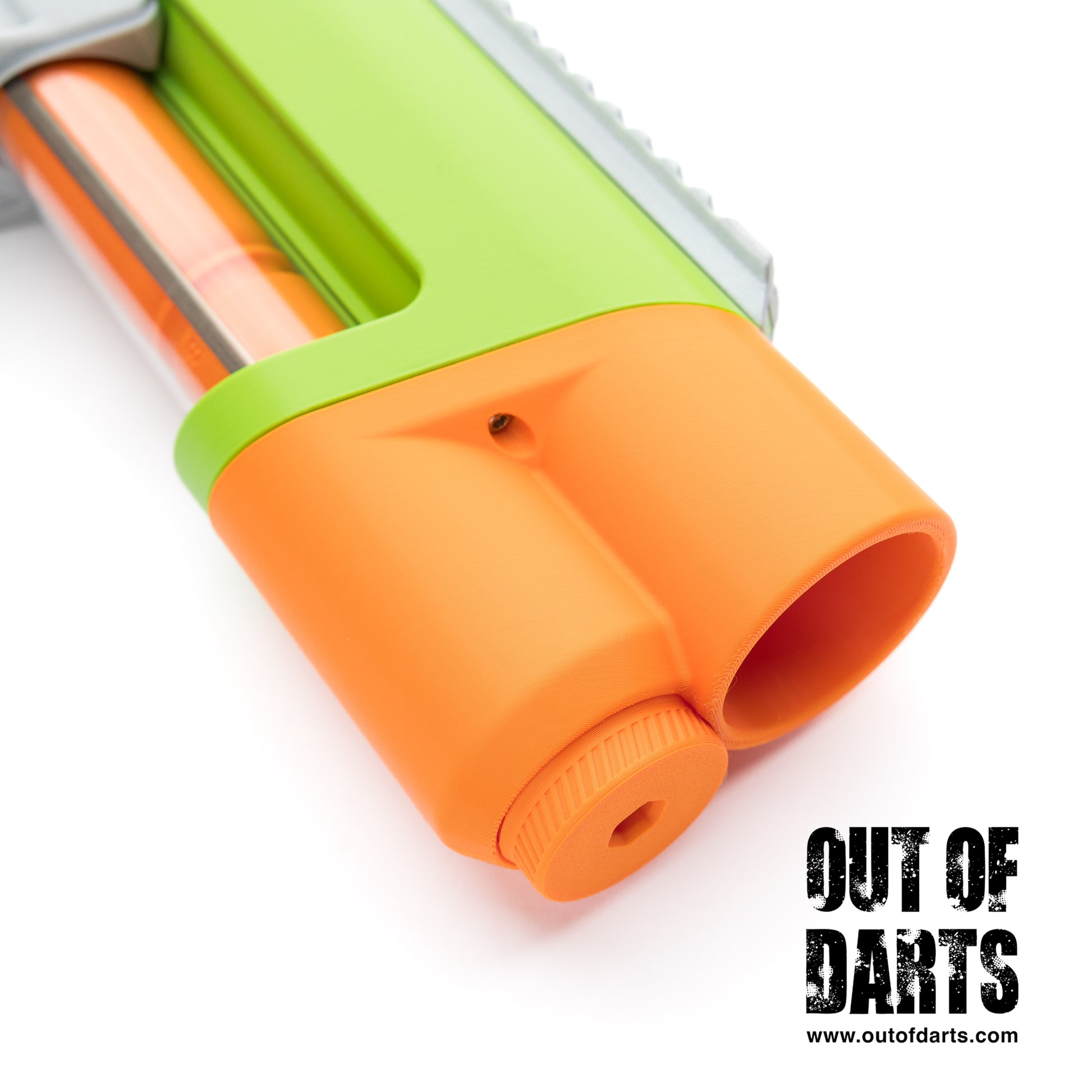

• Expandable internal tube magazine

• Mountable shell holders

• Bearing-assisted prime

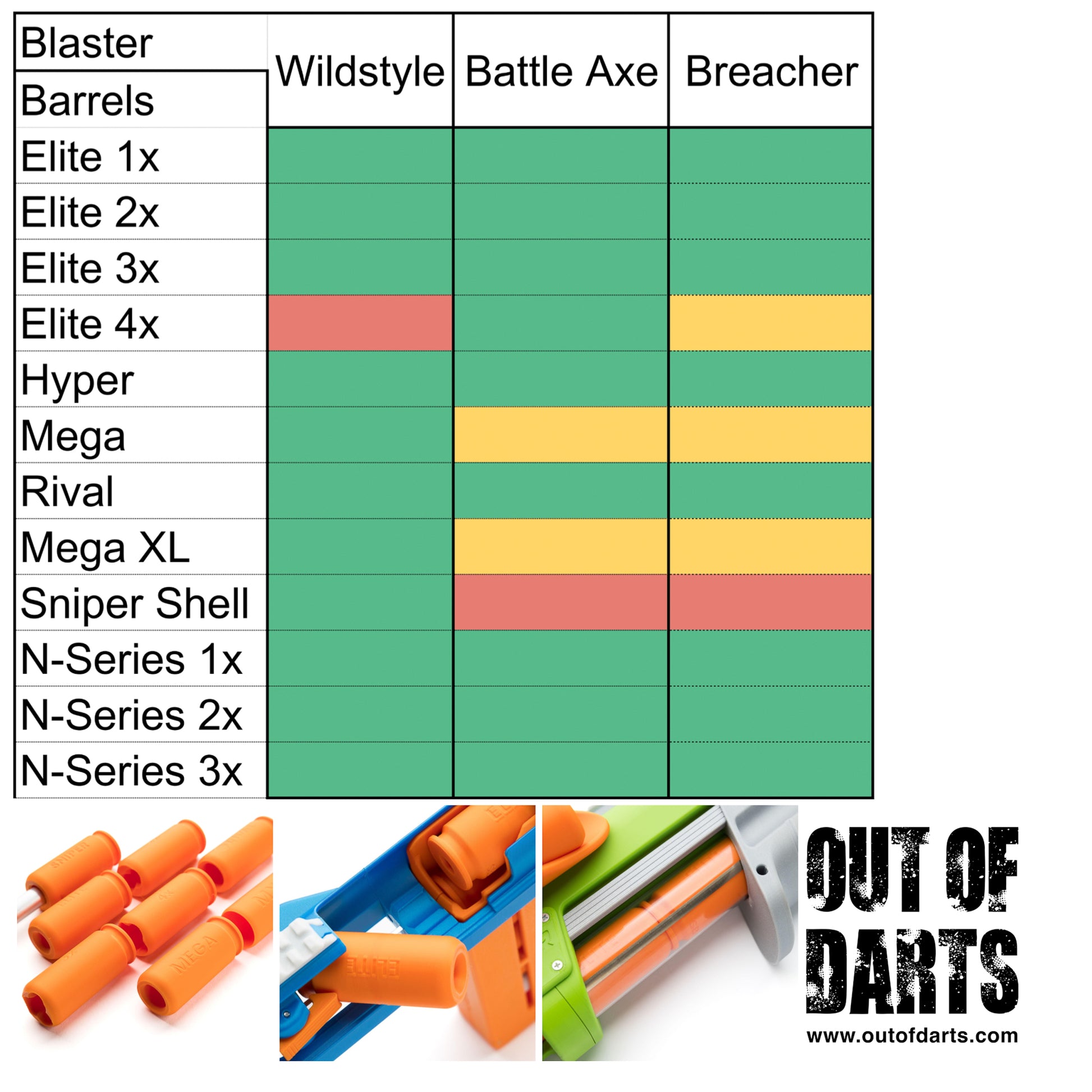

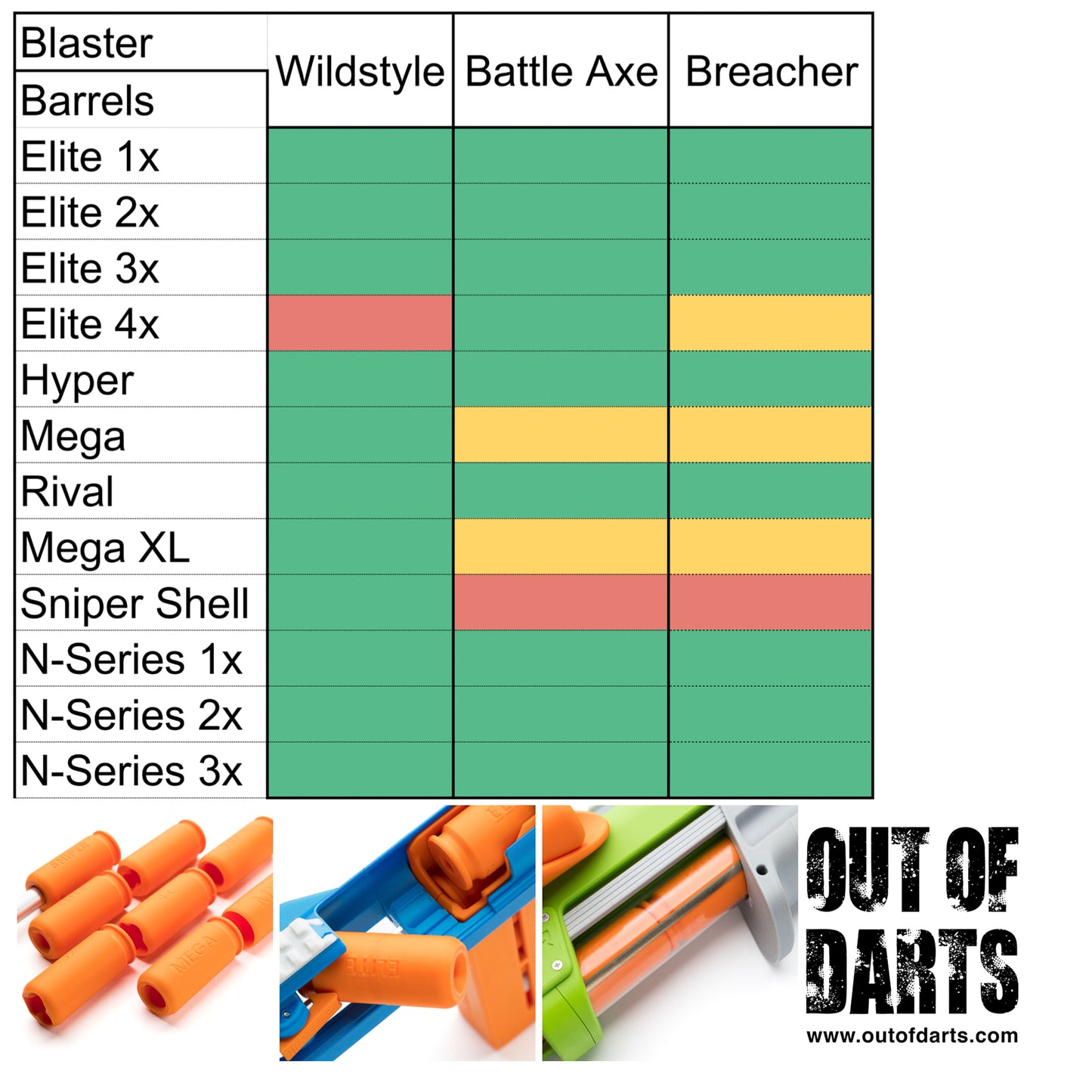

• Compatible with most Sillybutts Silly Shells

• Limited compatibility with longer shells and ammo types

INCLUDES:

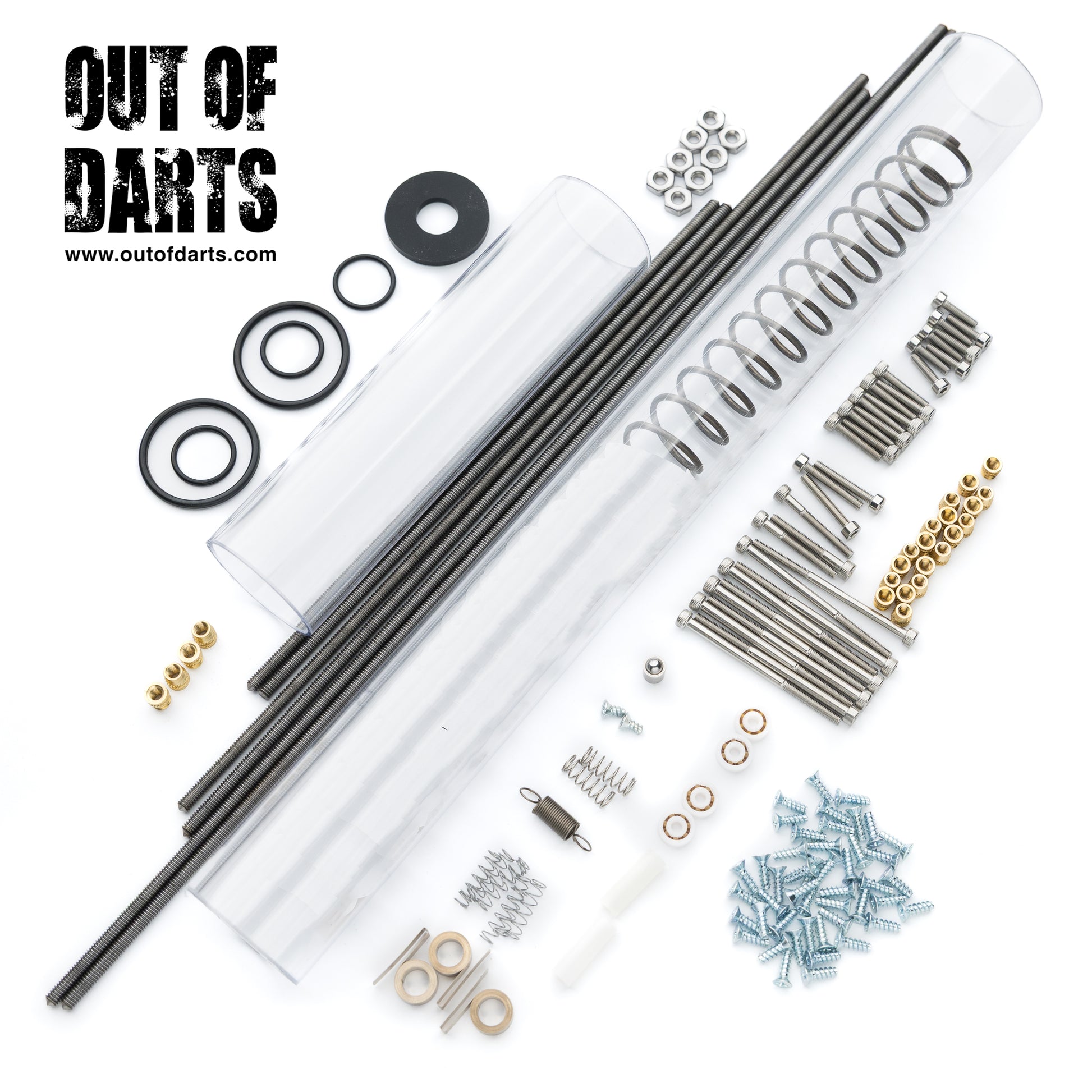

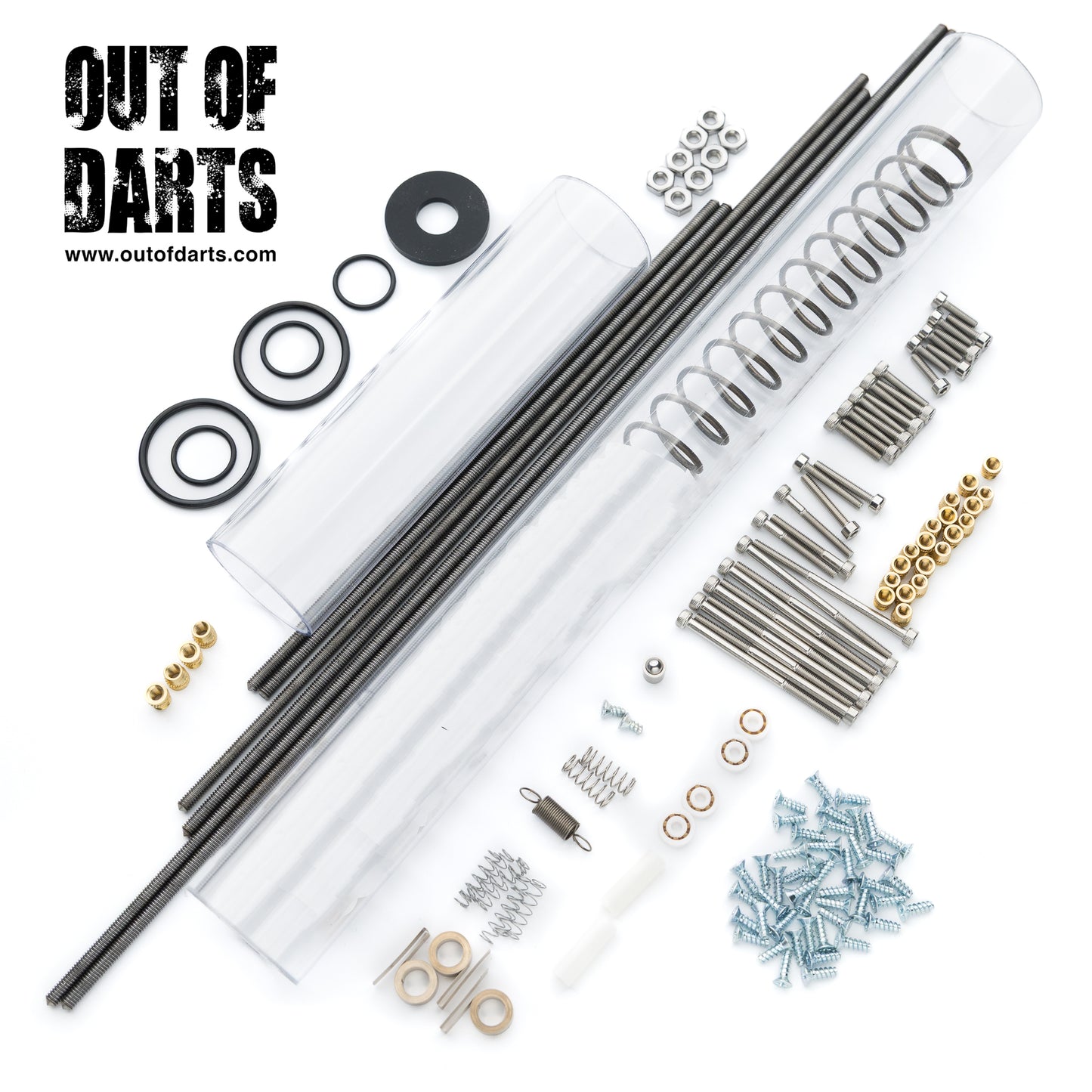

Everything you need to print and assemble this blaster yourself, including

• 1 2.0 x 150mm spring

• 3 Constant force mag springs

• 1 2mL bottle Slug Slym lubricant

PERFORMANCE:

Average FPS (Standard Deviation)

• 102 (3) FPS with Elite 1x shells and 1 short dart

SPECS:

• Material: Hardware

• Dimensions: Varies

• Weight: 380g

• Recommended Age: 14+

• SKU: HWK SIL BREACHER

LINKS:

• 3D files

• 3D Parts Kit

• Silly Shells

• More Breacher Mods + Accessories

• More Silly Shell-Fed Blasters

• Designer's website

Share

This is a review of the hardware kit, and not the design or function of the assembled blaster.

The hardware kit worked well with Silly's designs. I know there have been some complaints about the quality of the threaded rods, but I didn't have any issues with them. Mine were tapered well, straight, and easy to install. The acrylic tube for the magazine was indeed about a quarter inch too short, but the designer has since released an update to the files to include a shim for those who have been affected. I did measure my tube and it measures 13" just as the BOM suggests. So I'm not sure if it was an overall miscommunication between the designer and the supplier. Either way, my blaster ultimately functions as intended.

I got all the parts as listed including extra light springs and plenty of extra brass heat-set inserts for attachments and such. While my kit did come with extra inserts, those inserts were not accompanied by extra m3 screws.

Overall, I would purchase this kit again as it seems that any major issues described by previous reviews have been largely resolved. In fact, I may do just that since I'm giving this one away as a gift.

It only took me a few days to print all the parts using Inland PLA+ on a Creality Hi, but hardware shipping took multiple weeks due to delays and stock problems on their end. Aside from some mistakes on my end, assembly was straightforward with the video guide, but parts were either wrong or missing. Some M3 screws were missing which resulted in the lifter being nonadjustable, One of the long lead screws had messed up threading on one of the ends that made me **** in a nut the long way around, and the 016 O-rings were also the wrong size which had me going to a Home Depot and used Everbilt #75 O-rings as a replacement. Besides all these problems, the blaster was still really fun to assemble and fire. I really do hope these issues are fixed up once it's out of beta.

Hi Nullcat,

I'm sorry for any issues with the build. Since launch we've improved our QC process. Please reach out directly if we can get you any replacement parts or additional service!

My magazine tube was 12.75", a quarter inch short of the 13" the blaster was designed for. This means the tube can slide forward, and then the drum springs are free to slide out of place, bend, jam up the blaster, and eventually break. I was lucky enough to already have some compatible tube to make up for the missing length, and some extra drum springs, but most other nerfers would just be screwed.

Please check your stock and make sure this was a one-off problem, or you've got a ticking timebomb of complaints about malfunctioning blasters coming!

First time assembling a 3D printed springer and everything went very smoothly with very large exception of the long bars which just refused to thread with the included nuts like trying to mate metric with imperial. Lots of deburring got things as close as possible. Also, plastic bushings for the ammo holder springs would be preferred to the 3D printed ones I made. Final product works great with a bit of tinkering as defined by the instructions.

Hi Simon,

Sorry for the issues with the build and thank you for your feedback. We've improved our QC process and now which includes pre-threading hex nuts on both sides. Please let us know if we can help or offer any replacement parts.