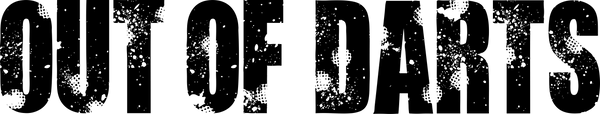

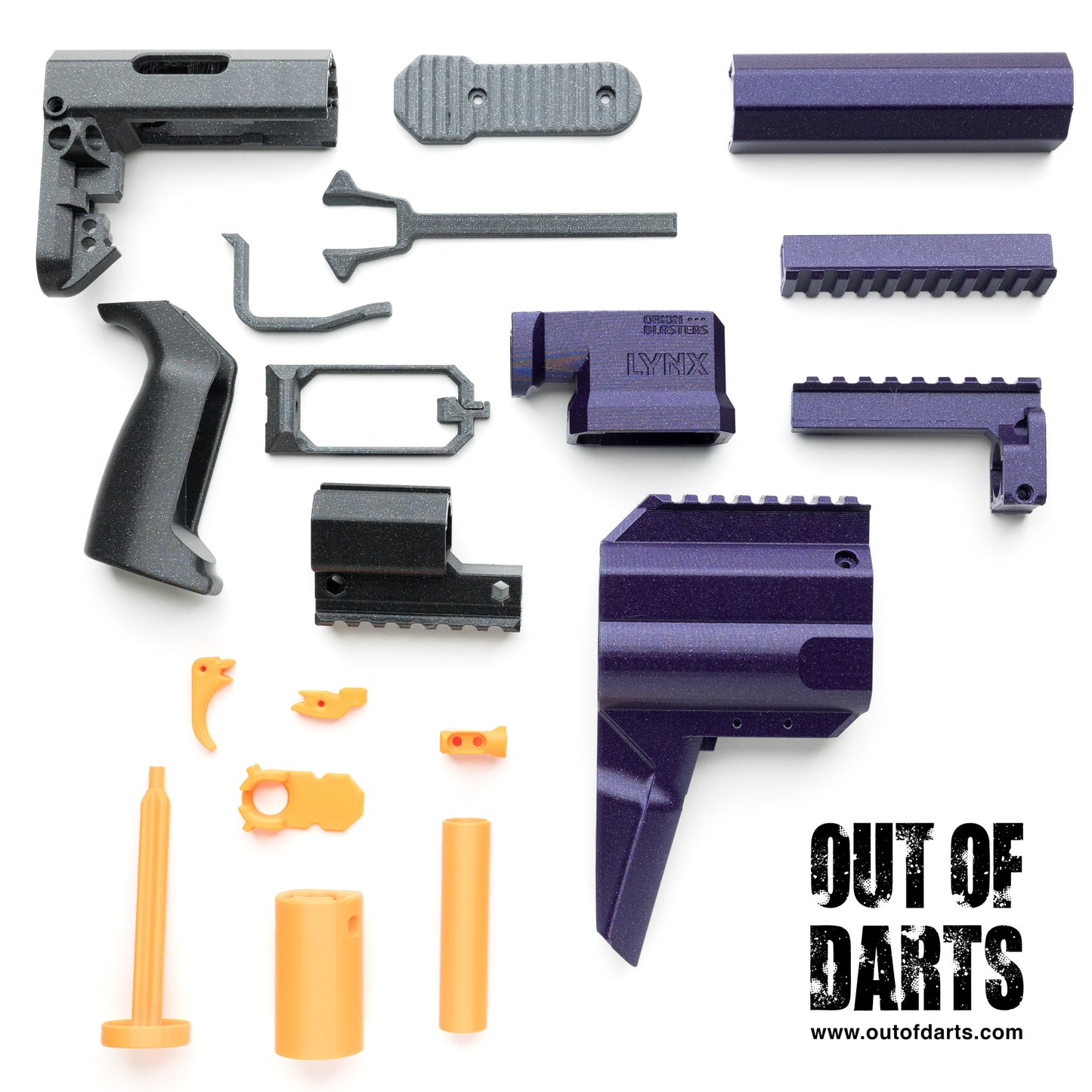

Orion Blasters Lynx 3D Parts + Hardware Kit

Orion Blasters Lynx 3D Parts + Hardware Kit

LEAD TIME: 1-2 WEEKS

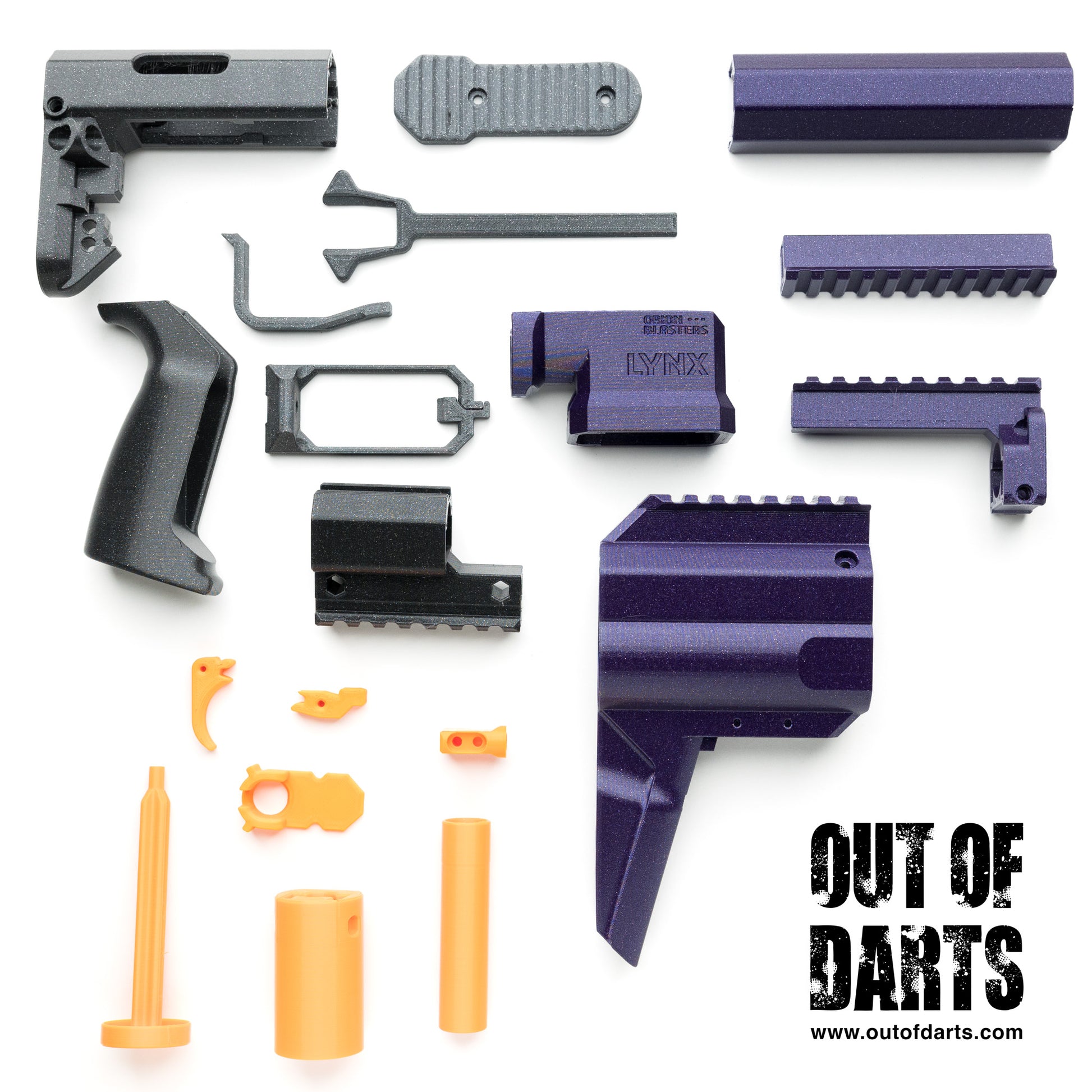

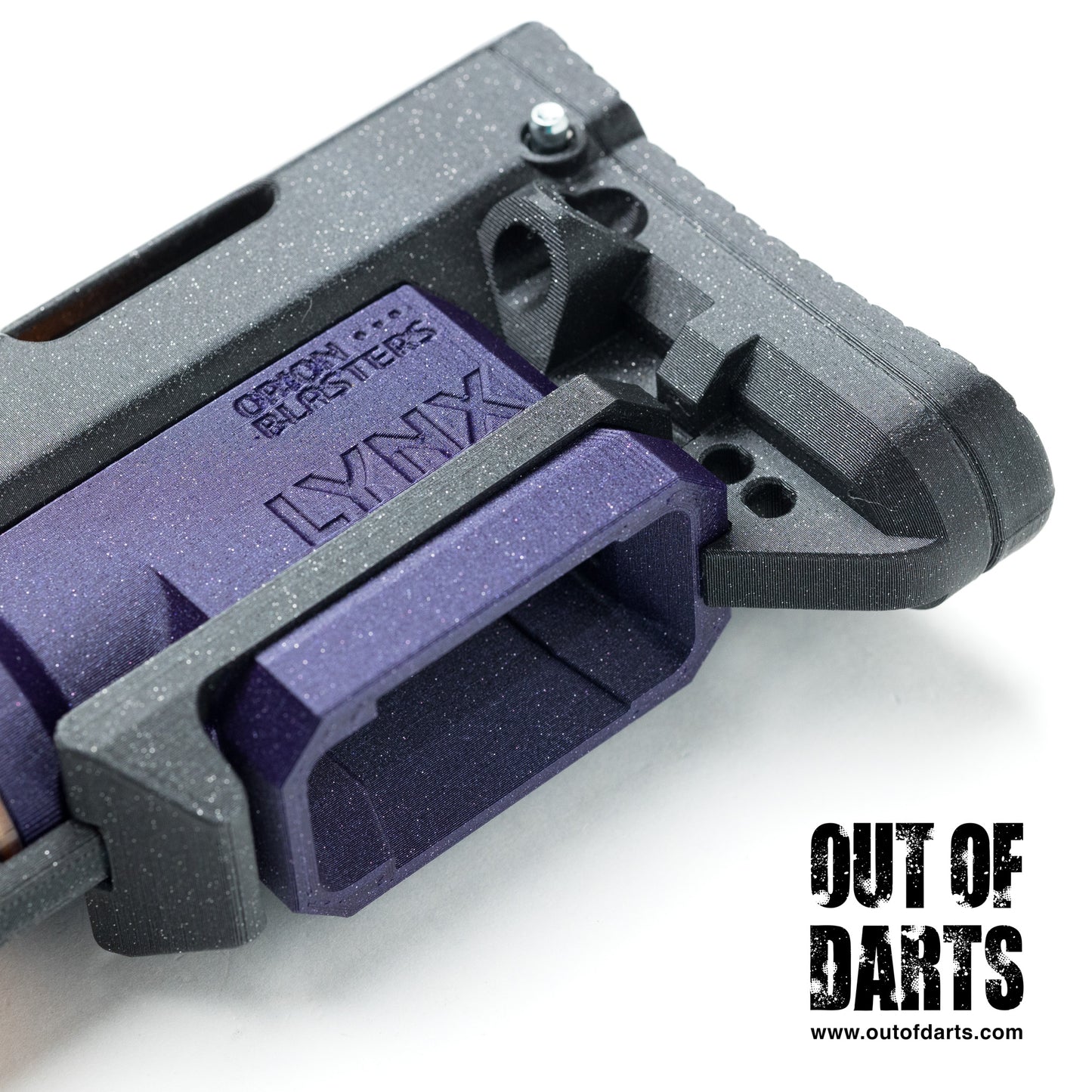

The Lynx 3D Parts + Hardware Kit is a complete kit, ready for you to assemble. The Lynx is a phenomenal high-performance bullpup-style blaster. The Lynx build is very straightforward and makes an excellent first-time build. Prefer to print your own? Check out our hardware kits here.

*Note; 15.5" barrel length is intended for use with a slim scar such as the OOD SCAR, Worker 8-line SCAR.

FEATURES:

• Print and build your own blaster with our hardware kit

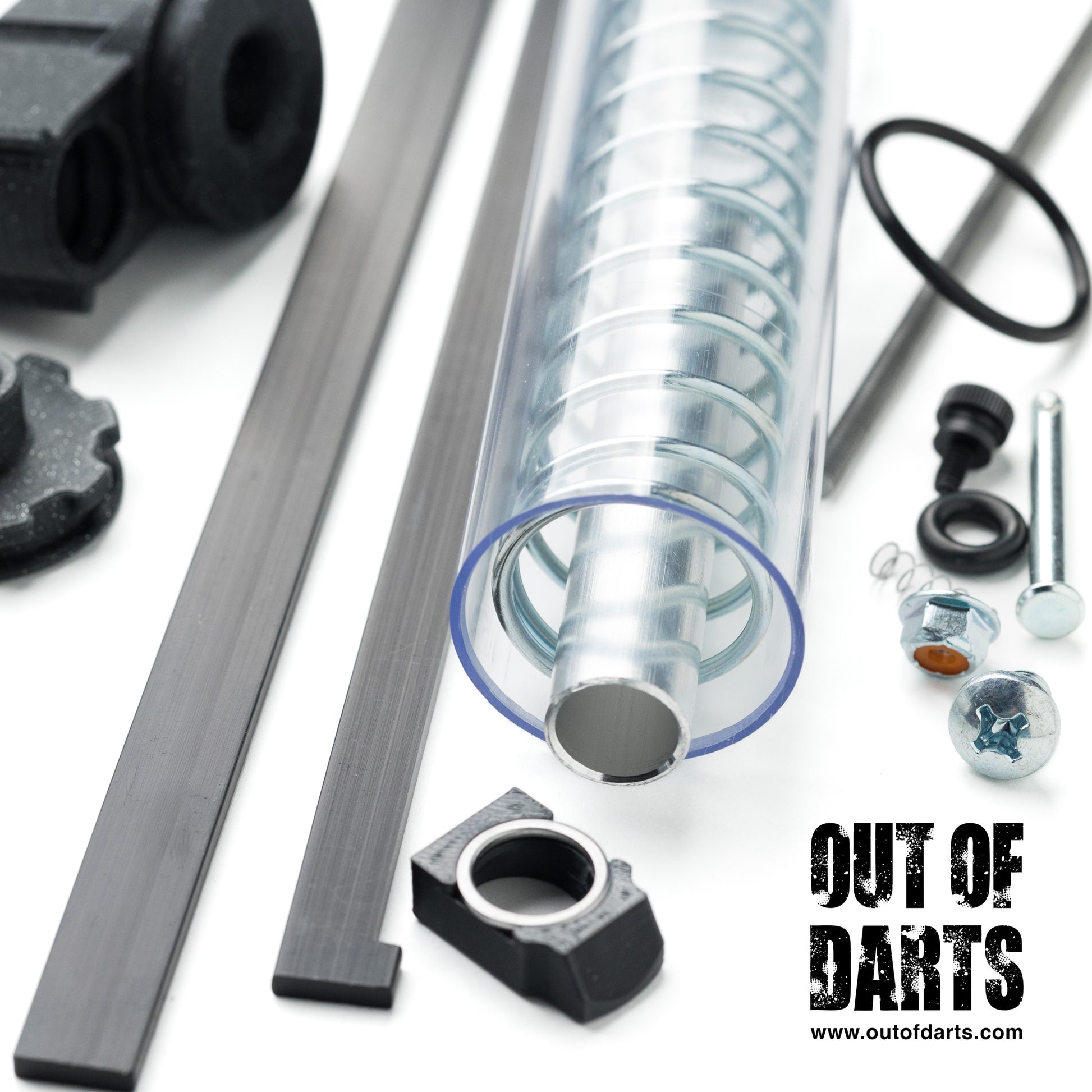

• Pump-action slam-fire bullpup

• Includes thumb magazine release

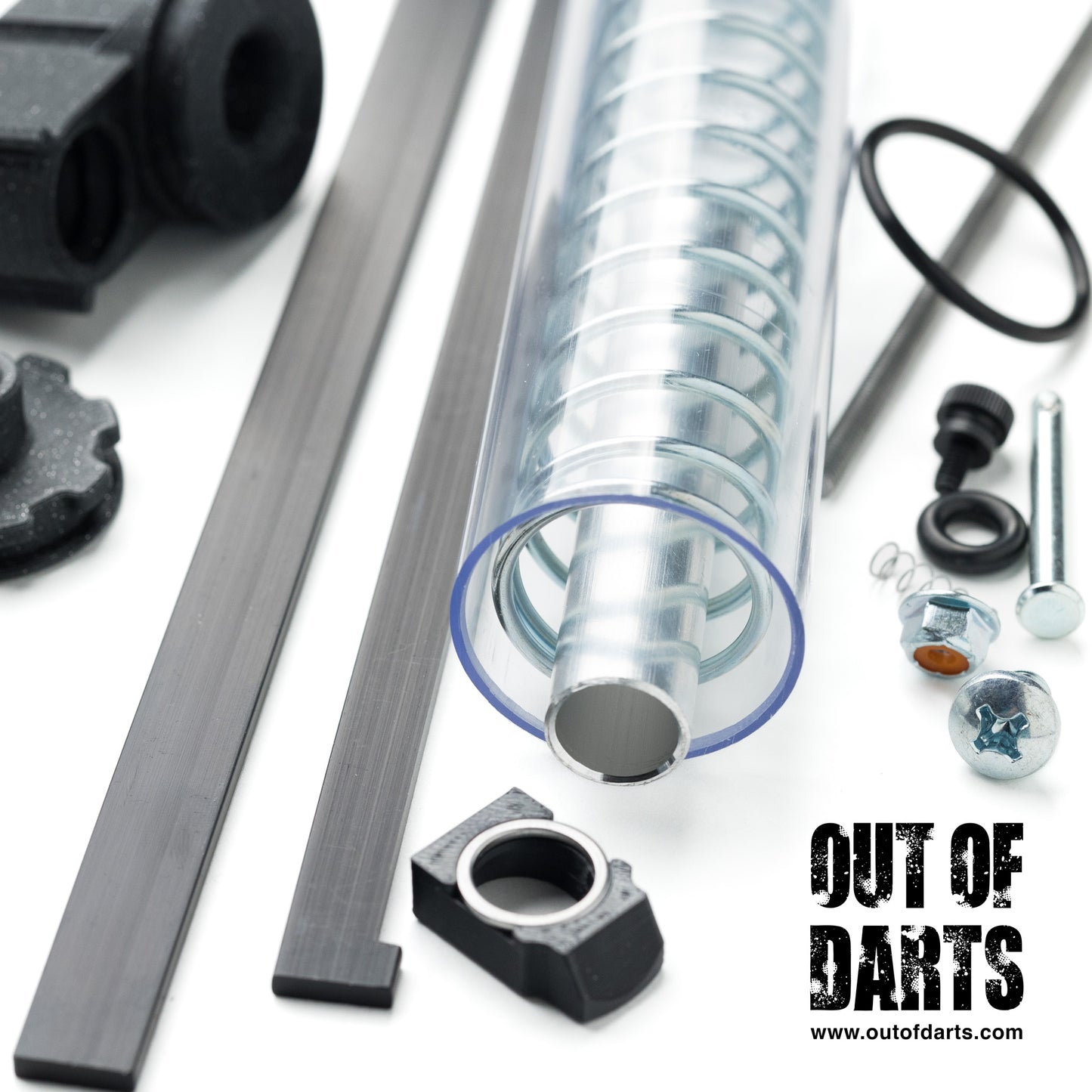

• Black anodizing optional for bars

• OOD 3D-Printed SCAR (not yet pictured) included with all Lynx blasters

• Metal catch with printed part to support higher spring loads

• Elegant, thoughtful design

• One of the easiest springer builds out there!

• Designed by Dan at Orion Blasters. Licensed with royalty and permission

• Does not include front grip

• Premium CNC aluminum bars

FPS/PERFORMANCE:

• FPS ratings are based on the standard barrel. Please note: changing the barrel length, barrel type, or adding a SCAR/BCAR will change these ratings.

• Spring data google sheet

SPECS:

• Material: Aluminum, Stainless steel, Spring steel, polycarbonate, PLA

• Dimensions:

• Weight: 1034 g

• SKU: LYNX_3DKIT

LINKS:

• Compatible Standard Talon Magazines

• Compatible Grip - Angled

• Compatible Grip - Vertical

Share

OUR FILAMENTS

We print primarily with Proto-Pasta HTPLA and PLA. Check out our full range of colors here.

3D printed parts should not be left inside hot cars or excessively hot environments.

Amazing kit and wonderful printing as always! Only docking a star because both of the mag releases/catch broke on attempting an install(that's mostly on me, just made me a bit frustrated) and didn't come with the thumb screws for the barrel. I was able to fix both problems, the mag release by plastic welding back together and the screws by taking one from my other lynx. (In the picture the OOD kit is the red and orange parts, the gold and blue are from Drac.)

Responding to this email to review. I bought a Worker Harrier, a Lynx 3D printed blaster, lots of darts and a few mags. My only real issue is that the 3d printed 'Catch 3' which rests on the spring, came broken and became unusable within an hour of gifting it to my son. Luckily I have access to a 3d printer and replaced the part and it's been fine.

Other than that, I enjoyed my Worker Harrier. Totally satisfying to upgrade the spring and catcher to put holes through my amazon boxes lol.

Hi Arthur,

Thanks so much for the feedback. We've now started including both the original spring rest and the updated 2.1 springg rest, which is substantially stronger and hasn't failed anyone yet. We hope this will help all future customers, especially those without printers.

This product performed very well and I have to say OOD did an fantastic job with the print quality

Almost been about a month since it has been marked shipped and has not moved from its starting location

Hi Matthew,

I'm sorry for any disspointment on delivery times for your custom printed and built blaster. You ordered December 18th, right at the end of our busiest season and just before our holiday break. Your Lynx was delivered on January 31st, which was within the quoted lead-time window at this time. We work our hardest to get orders printed and out as quickly as possible, but the nature of 3D prints and building blasters can require extra time.

Happy Modding,

Luke Goodman

OUT OF DARTS

orders@outofdarts.com

www.outofdarts.com

I ordered the hardware and parts and built the Lynx at home with my 9 year old son. It was east to assemble with the instructional video on the site. The blaster works perfectly and I would highly recommend.